Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

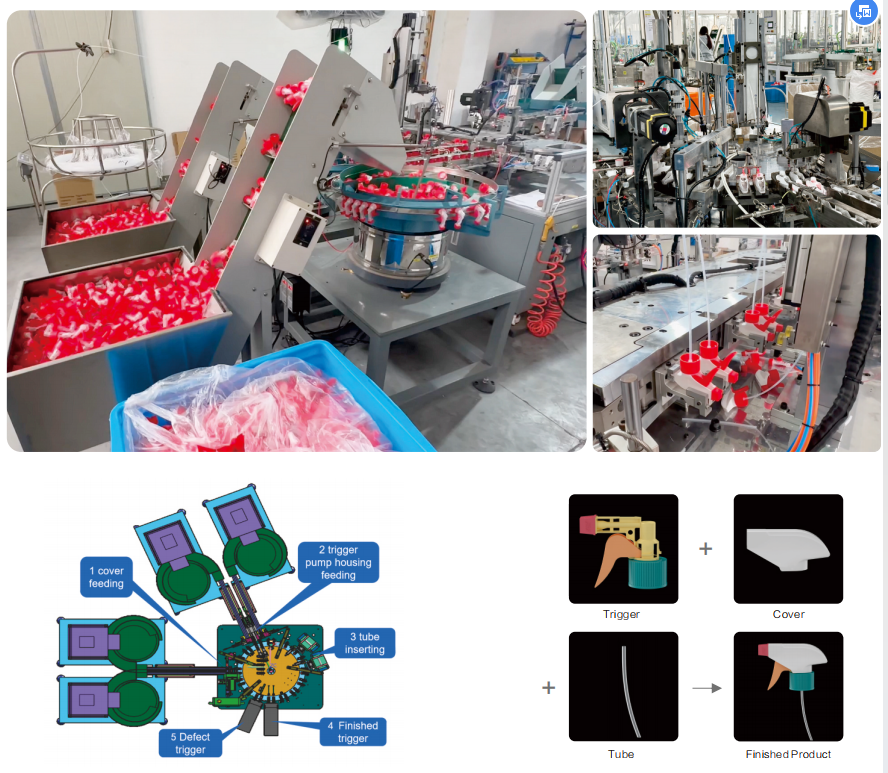

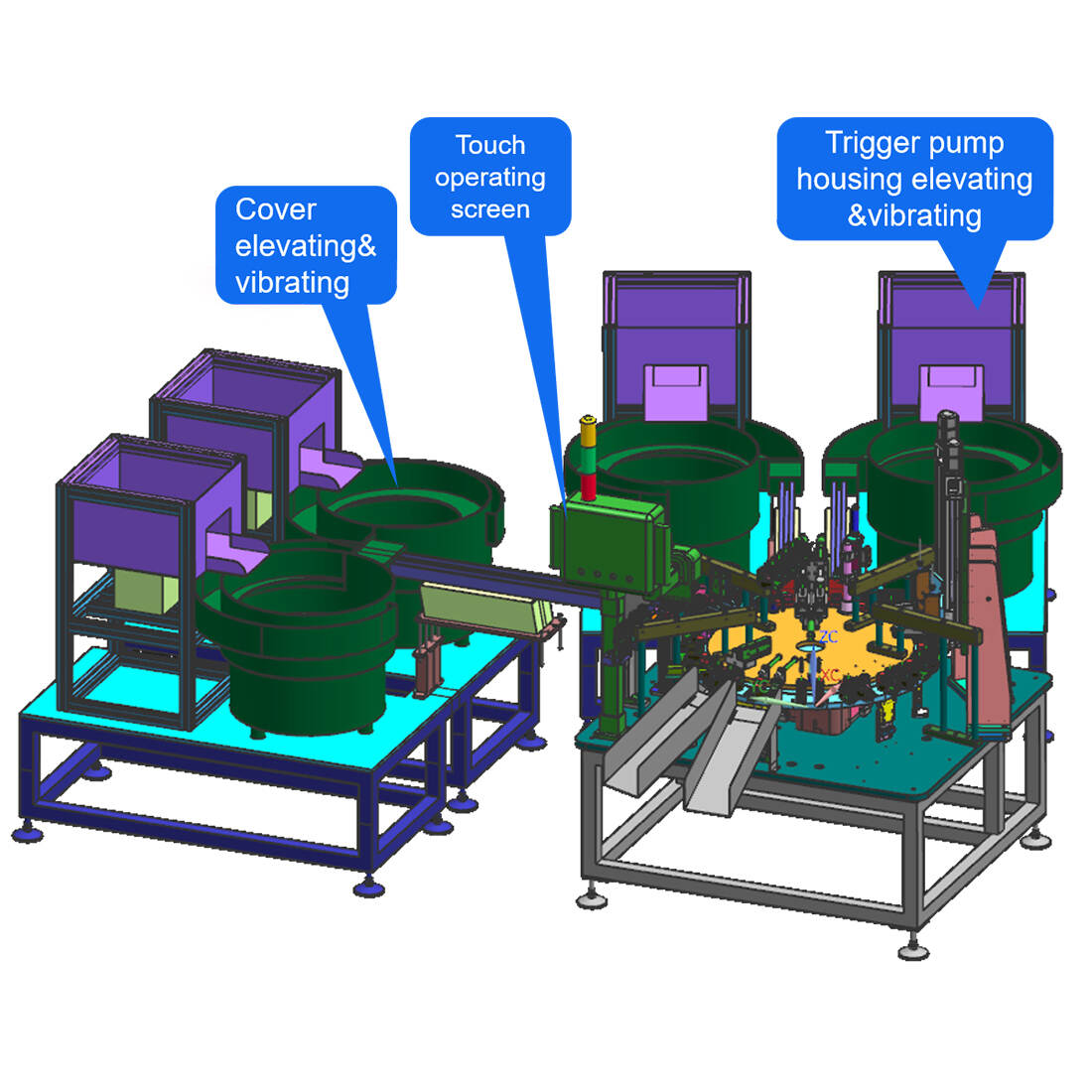

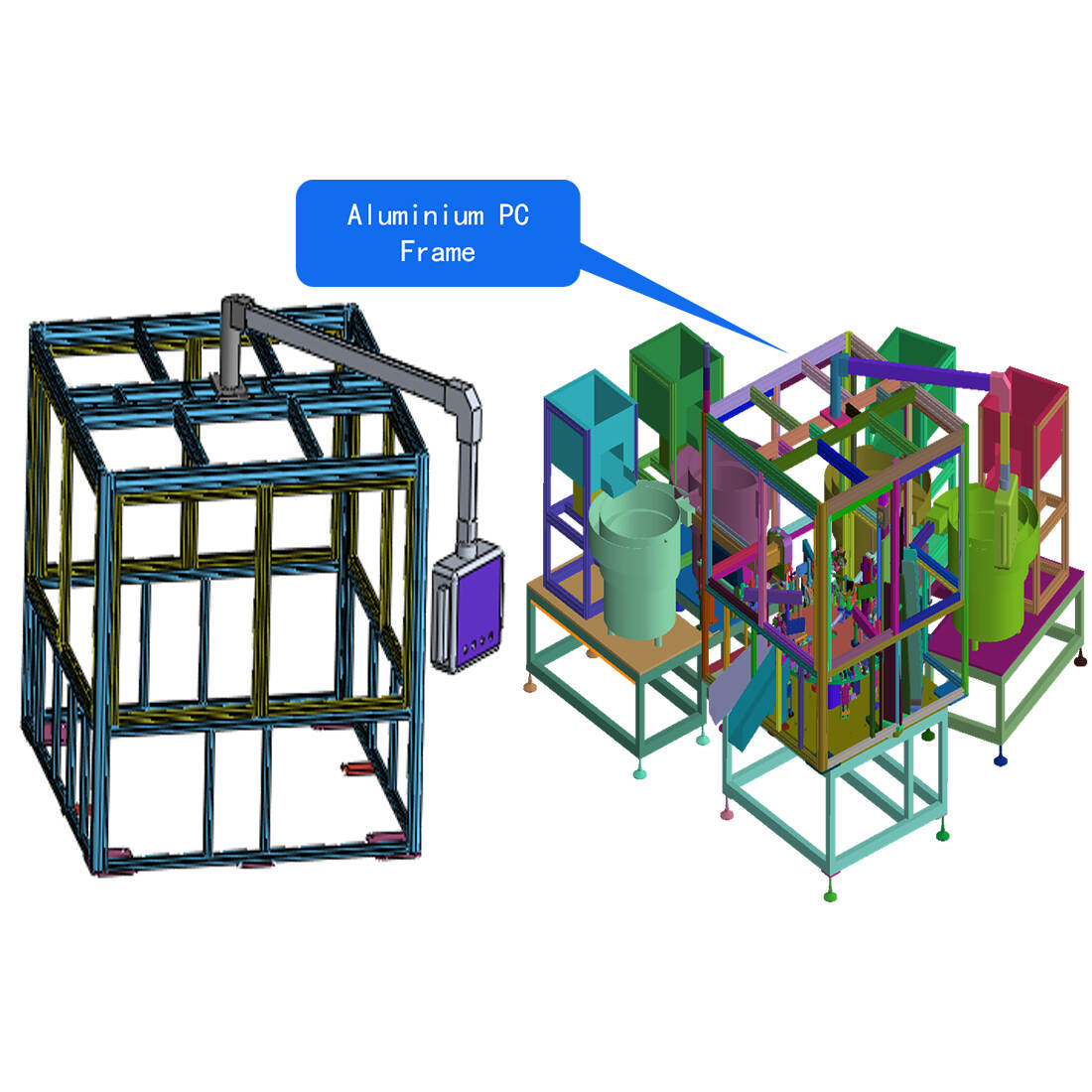

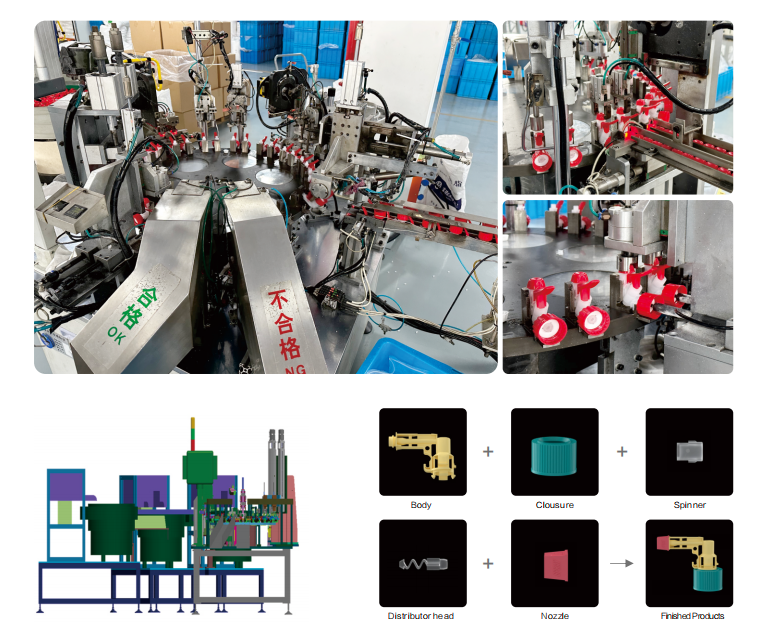

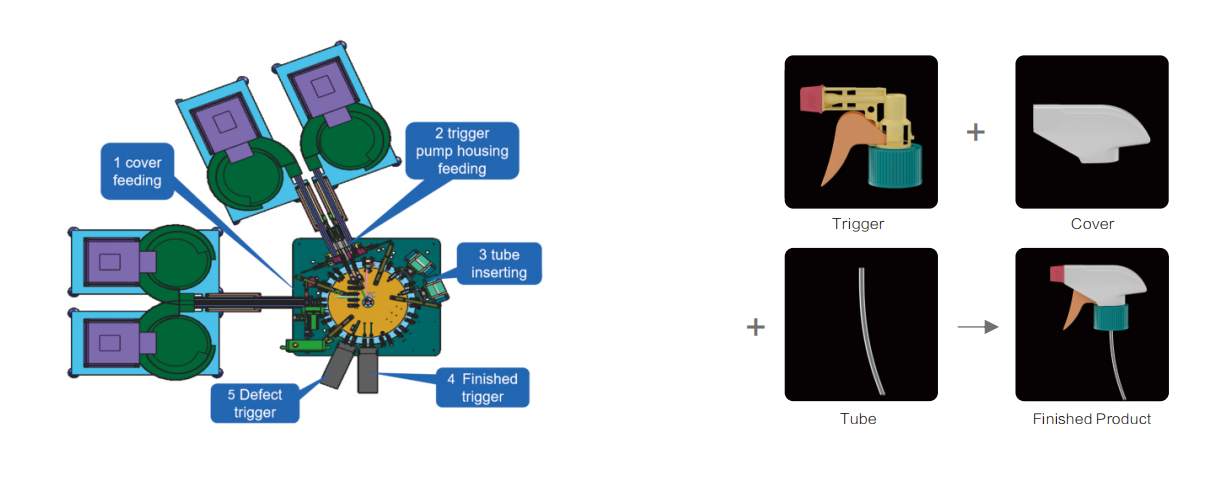

SR-TSM-05 Cover & Tube Insert Assembly Machine

Trigger Sprayer Cover & Tube Insert Assembly Machine

Voltage: 220V

Power: 4.5KW

Air Pressure: 0.6Mpa

Machine L*W*H: 3.82*3.6*1.8

Capacity/min : 55-64Pcs

Description

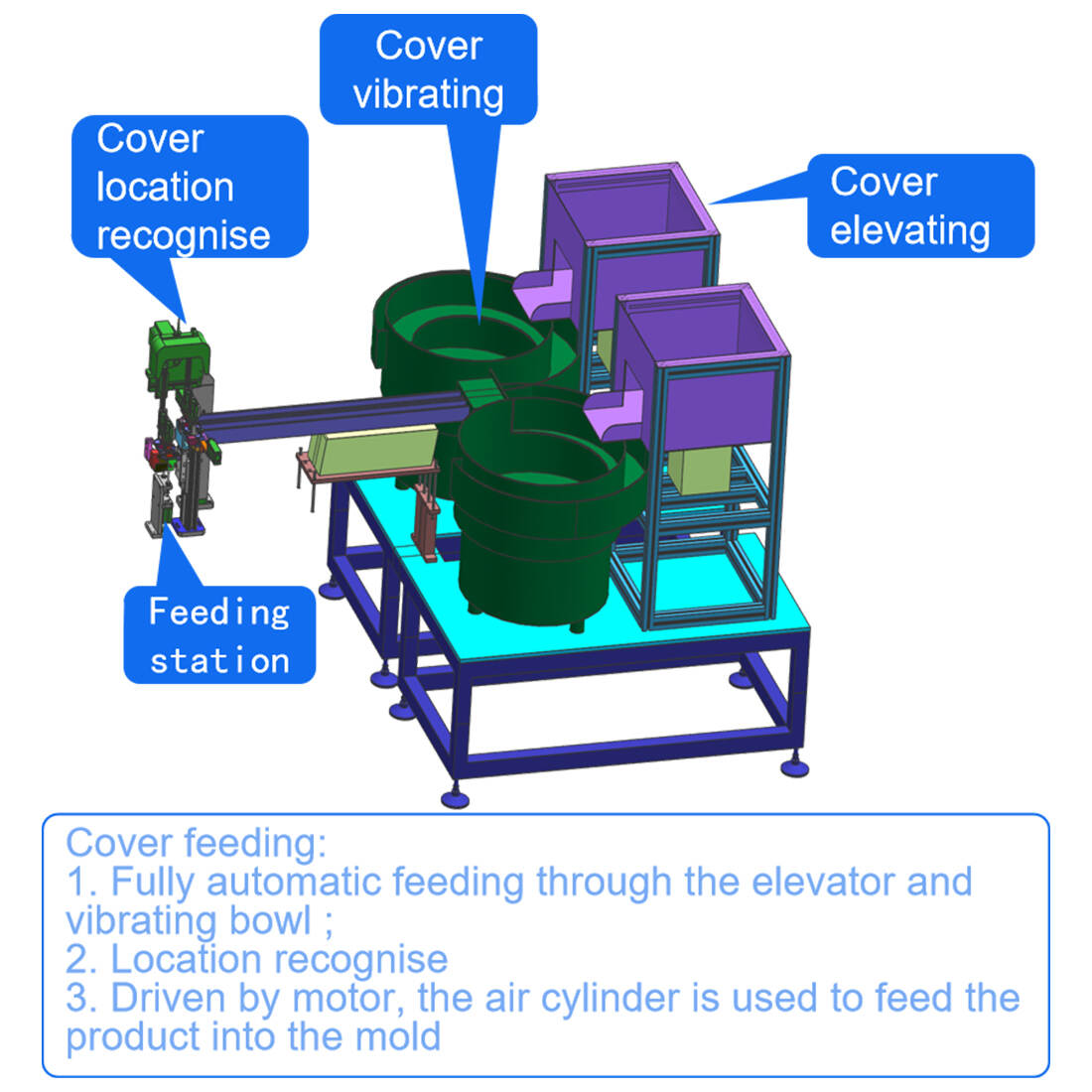

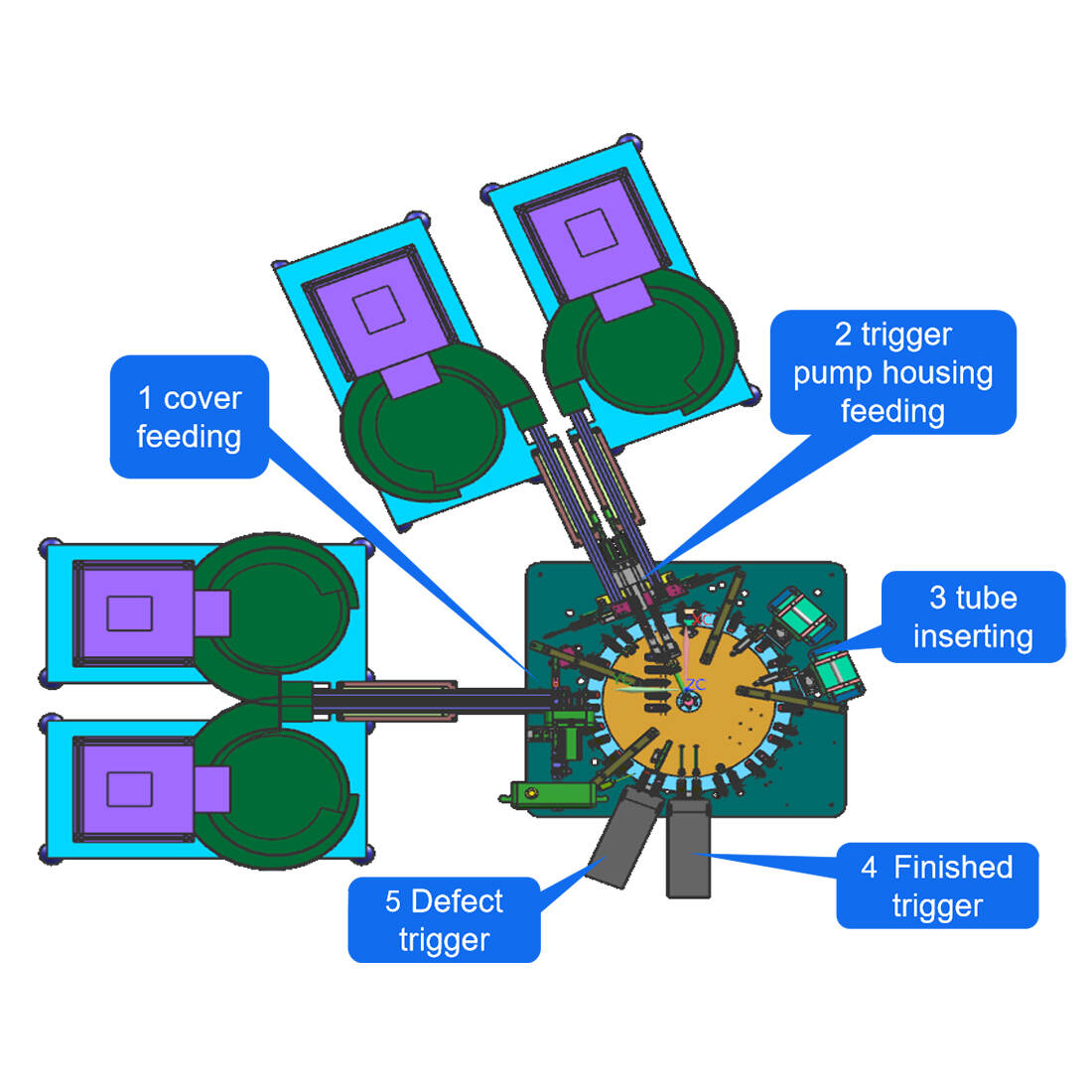

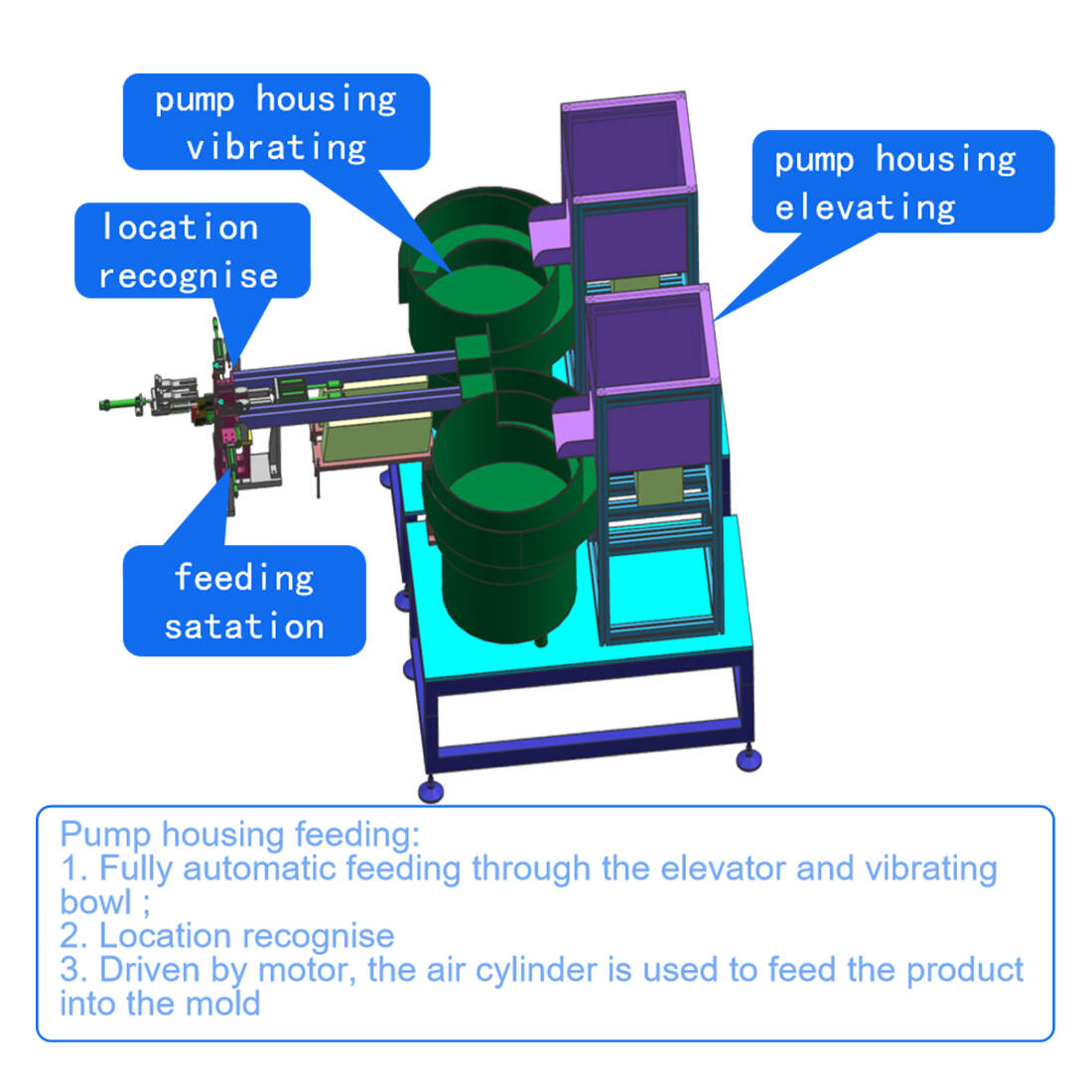

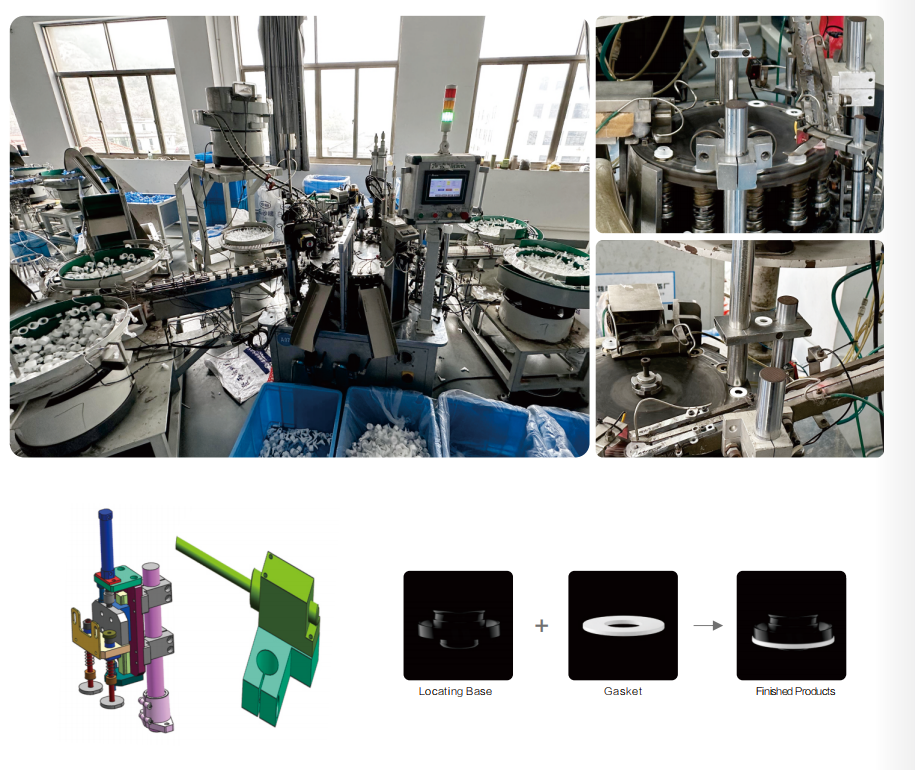

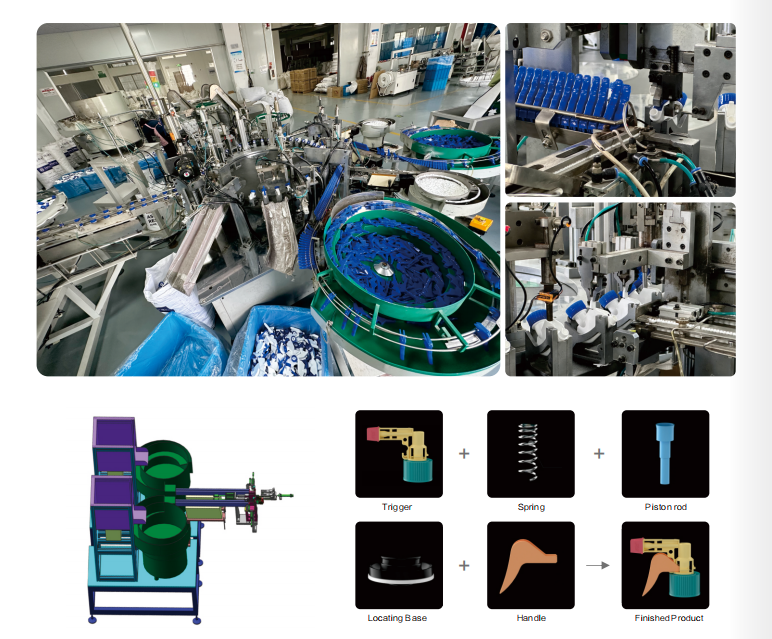

The trigger sprayer assembly machine is engineered to assemble a wide range of sprayer components with the utmost accuracy and efficiency. Whether it's trigger sprayers, press pump mechanisms, nozzles, or tubes, this versatile machine handles the assembly process seamlessly, ensuring consistent quality output. Its intelligent design allows for easy customization of functions and processes to meet specific production requirements.

Product Specification

| Main Component Configuration List | |||

|---|---|---|---|

| Project | Brand | Place of Origin | Remarks |

| PLC | Delta / Siemens | Taiwan, China / Germany | Customize |

| Servo Motor | Delta | Taiwan, China | Customize |

| Stepping Motor | Leisai / NBNCKJ / Inovance | China | Customize |

| Frequency Conversion Motor | Limin | China | Customize |

| Touch Panel | Weinview | China | Customize |

| Module | Dazzle | China | Customize |

| Guide Rail | Hiwin | Taiwan, China | Customize |

| Cylinder | Airtac / SMC / Festo | Taiwan, China / Japan / Germany | Customize |

| Barometer | Keyence | Japan | Customize |

| Non-Standard Component | Customize | China | Customize |

Product Features and Advantages

1. Versatile Assembly Capability: The machine is capable of assembling various types of sprayers, including trigger sprayers, press pumps, nozzles, and tubes, accommodating different specifications and models.

2. Intelligent Design: With an intelligent piece count display and defect detection functions, the machine ensures accurate assembly and detects any anomalies, minimizing the risk of defective products.

3. Customizable Functions: Manufacturers can easily customize the machine's functions and processes to align with specific production requirements, enhancing flexibility and adaptability.

4. High Precision: The machine boasts high accuracy in assembly, ensuring precise fitting of components and maintaining consistent quality across the production line.

5. Efficient Operation: Its fast speed, low noise levels, and stable performance contribute to enhanced productivity, reducing assembly time and increasing output capacity.

6. Reliable Performance: Built with robust construction and advanced technology, the machine offers reliable performance with fewer instances of jamming and downtime, thereby maximizing operational efficiency.

Benefits

- Rich Experience and Expertise: With Mr. Zhu Lishong, the founder, having over a decade of experience in the sprayer industry and the company's establishment in 2014, Songrock brings a wealth of knowledge and expertise to the table. This ensures that your products are handled by professionals who understand the nuances of the industry.

- Comprehensive Product Range: From plastic trigger sprayers to lotion pumps, mist sprays, and various personal care packaging products, Songrock offers a comprehensive range of accessories for daily use. Whether you need plastic bottles, airless bottles, essential oil bottles, or skin care sets, they have you covered.

Why Choose Us?

1: Are you a trade company or an manufacturing factory?

We are the Industry and trade integration company, we have our own manufactory.

2: How to get a quotation and start business relationship with your company?

First we need the photos of the item which you need the machine to assembl it, then we will send a information collection sheet to you, after all the informaton confirmed, we will send our quotation to you along with the delivery time and design drawing.

3: What's the minimum order quantity?

Our MOQ is 1 set of machine or one production line, we also sell product's mould as package, more quantity more discount.

4: Can you make customised automatic assembly machines(line)?

Yes, we can, and we are experienced in manufacturing customised automatic assembly machines (line).

5: What's the delivery time?

Normally the delivery time is 2-3 months.

6: How about the payment terms?

50% in advance,40% after machine finished, and balance 10% before delivering. T/T, Irrevocable L/C at sight are all acceptable

7: Do you provide on-site installation and Commissioning services?

Yes, we can provide on-site installation and Commissioning services, but the buyer have to bear the trip air tickets, accommodation, and labor subsidies,etc.

Please let me know if you have any questions, don't leave silently...